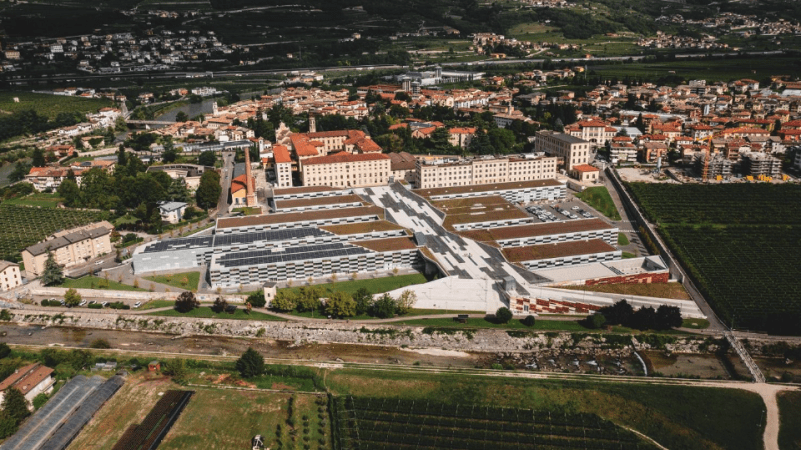

Progetto Manifattura

Geographical area: Europe

Location: Rovereto, Italy

City size: Small (between 50,000 and 250,000 inhabitants)

Promoter: Provincial Government of Trento

Developer: Manifattura Domani and Trentino Sviluppo

Start year:

End-year:

Implementation phase: Completed

Project size: Block

Total area of intervention (in sqm): 80.421

Total investments (in USD): 120 million

The redevelopment initiative Progetto Manifattura has been established as an innovation district focused on technologies and innovation targeted to sustainability and environmental issues. The Progetto Manifattura project originated from the redevelopment of a former tobacco manufacturing facility located in Rovereto, within the Trentino region. The industrial complex was owned by the British Italian Tobacco, the country branch of British American Tobacco. After the industry complex shut down, the area has been left abandoned with consequent degradation of the existing buildings. In addition, the site lacked proper connection and transportation options to connect it with the city center. To overcome these problems, the site has been acquired by the Provincial Government of Trento to host a redevelopment initiative. In 2008, the public company Trentino Sviluppo purchased the entire complex and started the renovation initiative. To conduct the entire redevelopment, Trentino Sviluppo and the Provincial Government of Trento founded the public development company Manifattura Domani. The company was appointed to oversee the planning, implementation and operational phases of the redevelopment project. With the support of local authorities and regional companies, the engineering firm ARUP, the consultancy firm Kanso, and the architectural firms Kengo Kuma and Associates and Carlo Ratti Associates developed the masterplan. The masterplan of the redevelopment envisions the creation of an innovation district focused on research, development, technical assistance, networking activities on sustainability, renewable energy, environmental technologies and sustainable construction industry. Secondly, the initiative will provide a testing plant to develop and implement architectural, engineering, systemic and energetic technologies and innovations. The masterplan divides the intervention between the renovation of the existing buildings of the former tobacco company and the creation of the new Be Factory complex. The first phase of the implementation involved the renovation of the existing Building 1 and Building 14 of the former tobacco factory. The second phase saw the demolition and renovation related to the remaining existing buildings, and the creation of the trigeneration production plant. The third phase included the partial construction of the car parking area and the initial construction of the new light wooden buildings of the Be Factory. The final fourth phase saw the completion of the car parking spaces, the Be Factory buildings and the installation of the final trigeneration plant. Both the renovated buildings and the newly developed spaces will host companies, research centers and laboratories focused on environmental and sustainability-related innovation and technologies. In addition, the project will provide the district with a restaurant and a café to serve the companies and visitors of the site. The implementation works have been conducted by Colombo Costruzioni, and the construction works of the entire site concluded in September 2020. The innovation district will be entirely managed by the public company Trentino Sviluppo Spa, owned by the Provincial Government of Trento. The public company holds the property of the renovated and new buildings, is appointed to manage the operations of the activities conducted on the district and to stipulating renting contracts with companies, laboratories, research centers and universities. As a green innovation district, Progetto Manifattura focuses on providing research centers, startups, innovation firms and technology companies with a space and testbed to develop new technologies related to sustainability and green economy, such as sustainable mobility options, low-impact construction materials and smart building technologies. Thanks to the focus on reducing environmental impact, the initiative achieved a great emissions reduction with the renovation of existing facilities and the creation of low-impact buildings. In addition, the Progetto Manifattura gave a strong boost to sustainable mobility by implementing bicycle paths, open spaces, low-emission shuttle services and sharing options for both employees and visitors.

Land use zoning

The renovated existing factory buildings hosts different companies, startups, research centers on bioinformatics, medical sciences, sport and environmental issues, and spaces for the University of Trento and the University of Verona. The spaces created with the new buildings of the Be Factory are allocated to industrial production and laboratories for innovation companies, and a smaller section hosting restaurant, museum, gym, and training center. The site hosts also 700 car parking spots for employees and visitors, as well as a station for car-sharing vehicles. In addition, part of the surface is dedicated to open spaces, green areas, pedestrian paths and bicycle lanes.

Economic

The main economic impact brought by the regeneration initiative is the creation of a new innovation district focused on environmental and sustainability-related topics. The renovated area hosts around 80 companies and public and private research centers targeting innovative technologies. The new district hosts 40 local companies from the Trentino region, thus significantly fostering regional development and supporting local businesses. The project focuses on attracting innovation and technology-related firms, such as building and engineering companies, private and universities research centers, university departments and experimental laboratories. In addition, the initiative provides support to local businesses, innovation companies and green startups by creating a collaborative environment, equipped with productive spaces, laboratories and testbeds to grow their business and develop technological solutions. The project provides fully equipped laboratories and working spaces to better serve innovation and technology firms. In total, the project and the hosted companies employ around 600 workers.

Environmental

As a green innovation district, the initiative focuses on renovating and creating a sustainable district, reducing both emissions and energy consumption. Firstly, the construction of new buildings and the renovation of the existing industrial complex employed low-emission materials and innovative construction technologies to reduce the emission during the construction works. In addition, half of new buildings are constructed to be carbon neutral. To reduce emissions, the district employs a new energy production system by installing a trigeneration plant to serve the entire site and connected to the district heating network. The district heating is managed by Habitech. The newly built plant has yearly production levels of 6,400 MWh for thermal energy, 270 MWh for cooling energy and 4,200 MWh for electricity. The production of energy for heating comes from biomass Combined Heat & Power plants (80%), heat pumps (10%) and from high-efficiency gas boiler (10%). The 58% of the production of electricity comes from renewable resources, with 20% coming from hydroelectric and 38% from biomass. The energy production for cooling systems comes from biomass Combined Heat & Power plants (60%), heat pumps (25%), and electric chillers (15%). Lastly, the initiative also installed solar photovoltaic panels to recharge electric car vehicles with an installed power of 730 kW. The initiative achieved a great reduction in energy demand from both existing and new buildings. All the new buildings of the Be Factory are certified with energy class A, while the renovated buildings have been renewed to achieve a minimum energy class of C/D. In total, the project achieved the reduction of 70% of the primary energy demand from non-renewable sources, while 52% of the peak power needed are covered by energy from renewable sources. The energy improvement of both the existing and new buildings brought a significant reduction in greenhouse gases emissions. During the operational phase, emissions will be reduced by 70% in buildings, transportation and infrastructures compared to business-as-usual standards. In addition, the demolition, construction, renovation and waste management processes will reduce emissions by 20% in relation to business-as-usual standards. The reduction of emissions is calculated with business-as-usual standards, which are calculated from National legislations on energy requirements and from the estimated energy consumption of the existing buildings at pre-intervention stage. In addition, the new production of electricity and thermal energy reduced CO2 emissions by 80% and 85%, respectively. Sustainability is also achieved through food production. The cafeteria and restaurant present in the area will locally produce their own food or serve from suppliers within a range of 100 km to reduce food transportation and support local producers. The new water management system has been improved, with the collection and reuse of rainwater and wastewater that will satisfy 28% and 29% of the water demand of the entire complex. Lastly, to ensure natural and open spaces for visitors and employees, the site has been covered with 28,000 sqm of green areas.

Social

Certificates

The new buildings of the Be Factory achieved the Gold level certification of the LEED BD+C New Construction v4, which set environmental criteria for newly constructed buildings and major renovations, and the ARCA Silver Certification level for the wooden buildings of the Be Factory.

Funding source

The redevelopment of the tobacco factory has been entirely funded by the National Government of Italy, the Provincial Government of Trento and the European Union. The total costs of the initiative amounted to around USD 110 million, employed by the Provincial Government of Trento to acquire the site, renovate the existing buildings and develop the new spaces. The Development and Cohesion Fund, managed by the National Government of Italy, provided USD 96 million (80%). The remaining costs has been funded by the European Regional Development Fund.

Financing and economic instruments

The Provincial Government of Trento financed the acquisition of the factory site and the public company Manifattura Domani employing resources from the Development and Cohesion Fund, managed by the National Government of Italy and from the European Regional Development Fund. The Municipality of Rovereto adopted a variation of the land use of the site, modifying the previous historical buildings status through a variation in the General Regulatory Plan of the Municipality. The instruments increased the land value of the site and allowed the establishment of companies, research centers and laboratories.

References

U.S. Green Building Council. Progetto Manifattura Ambito B – Lotto 1. Accessed on 04/07/2024. Available here.

Progetto Manifattura (2021). Be Factory ottiene la certificazione ARCA Silver. Accessed on 04/07/2024. Available here.

Be Factory – Progetto Manifattura official website. Accessed on 04/07/2024. Available here.

Progetto Manifattura official website. Accessed on 04/07/2024. Available here.

Progetto Manifattura (2010). Green Innovation Factory. Available here.

Infobuild (2021). La Be Factory di Rovereto. Accessed on 04/07/2024. Available here.

Colombo Costruzioni. Progetto Manifattura – Green Innovation Factory Project. Accessed on 04/07/2024. Available here.

SCE Project. Progetto Manifattura – Green Innovation Factory Project. Accessed on 04/07/2024. Available here.

Municipality of Rovereto. PRG - variante Manifattura Tabacchi. Accessed on 11/10/2024. Available here.

Credits

Image from Trentino Sviluppo, retrieved here.